The type of instrument to be purchased for general use in the electrotechnical

industries is a difficult choice because there are so many different

types on the market and every manufacturer’s representative is convinced

that his company’s product is the best. However, most instruments can be

broadly grouped under two general headings: those having analogue and

those with digital displays.

Analogue meters have a pointer moving across a calibrated scale. They are

the only choice when a general trend or variation in value is to be observed.

Hi-fi equipment often uses analogue displays to indicate how power levels

vary with time, which is more informative than a specific value. Red or

danger zones can be indicated on industrial instruments. The fuel gauge

on a motor car often indicates full, half full or danger on an analogue display

which is much more informative than an indication of the exact number

of litres of petrol remaining in the tank.

These meters are only accurate when used in the calibrated position – usually horizontally.

Most meters using an analogue scale incorporate a mirror to eliminate parallax error. The user must look straight at the pointer on the scale when taking readings and the correct position is indicated when the pointer image in the mirror is hidden behind the actual pointer. That is the point at which a reading should be taken from the appropriate scale of the instrument.

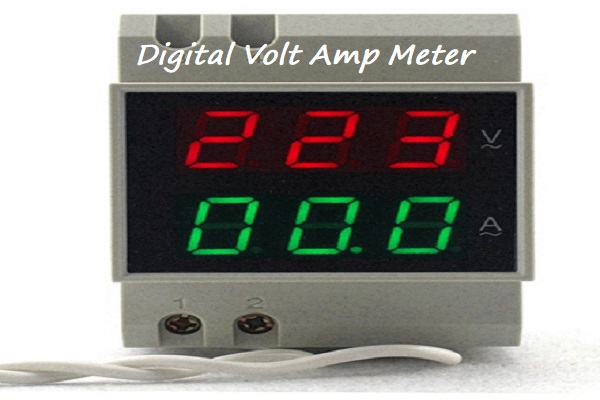

Digital meters provide the same functions as analogue meters but they display the indicated value using a seven-segment LED to give a numerical value of the measurement. Modern digital meters use semiconductor technology to give the instrument a very high-input impedance, typically about 10 MΩ and, therefore, they are ideal for testing most electrical or electronic circuits.

The choice between an analogue and a digital display is a difficult one and must be dictated by specific circumstances. However, if you are an electrician or service engineer intending to purchase a new instrument, I think on balance that a good-quality digital multimeter such as that shown in Picture would be best. Having no moving parts, digital meters tend to be more rugged and, having a very high-input impedance, they are ideally suited to testing all circuits that an electrician might work on in his daily work.

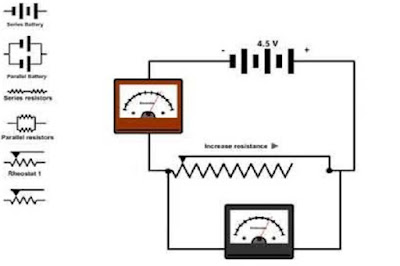

Multimeters are designed to measure voltage, current or resistance. Before taking measurements the appropriate volt, ampere or ohm scale should be selected. To avoid damaging the instrument it is good practice first to switch to the highest value on a particular scale range. For example, if the 10 A scale is first selected and a reading of 2.5 A is displayed, we then know that a more appropriate scale would be the 3 A or 5 A range. This will give a more accurate reading which might be, say, 2.49 A.When the multimeter is used as an ammeter to measure current it must be connected in series with the test circuit.

When used as a voltmeter the multimeter must be connected in parallel with the component.

When using a commercial multirange meter as an ohmmeter for testing electronic components, care must be exercised in identifying the positive terminal. The red terminal of the meter, identifying the positive input for testing voltage and current, usually becomes the negative terminal when the meter is used as an ohmmeter because of the way the internal battery is connected to the meter movement. Check the meter manufacturers handbook before using a multimeter to test electronic components.

Analogue meters or instruments

These meters are only accurate when used in the calibrated position – usually horizontally.

Most meters using an analogue scale incorporate a mirror to eliminate parallax error. The user must look straight at the pointer on the scale when taking readings and the correct position is indicated when the pointer image in the mirror is hidden behind the actual pointer. That is the point at which a reading should be taken from the appropriate scale of the instrument.

Digital meters or instruments

Digital meters provide the same functions as analogue meters but they display the indicated value using a seven-segment LED to give a numerical value of the measurement. Modern digital meters use semiconductor technology to give the instrument a very high-input impedance, typically about 10 MΩ and, therefore, they are ideal for testing most electrical or electronic circuits.

The choice between an analogue and a digital display is a difficult one and must be dictated by specific circumstances. However, if you are an electrician or service engineer intending to purchase a new instrument, I think on balance that a good-quality digital multimeter such as that shown in Picture would be best. Having no moving parts, digital meters tend to be more rugged and, having a very high-input impedance, they are ideally suited to testing all circuits that an electrician might work on in his daily work.

Multimeter

Multimeters are designed to measure voltage, current or resistance. Before taking measurements the appropriate volt, ampere or ohm scale should be selected. To avoid damaging the instrument it is good practice first to switch to the highest value on a particular scale range. For example, if the 10 A scale is first selected and a reading of 2.5 A is displayed, we then know that a more appropriate scale would be the 3 A or 5 A range. This will give a more accurate reading which might be, say, 2.49 A.When the multimeter is used as an ammeter to measure current it must be connected in series with the test circuit.

When used as a voltmeter the multimeter must be connected in parallel with the component.

When using a commercial multirange meter as an ohmmeter for testing electronic components, care must be exercised in identifying the positive terminal. The red terminal of the meter, identifying the positive input for testing voltage and current, usually becomes the negative terminal when the meter is used as an ohmmeter because of the way the internal battery is connected to the meter movement. Check the meter manufacturers handbook before using a multimeter to test electronic components.

Post a Comment