The cables can be considered to be constructed in three parts: the conductor which must be of a suitable cross-section to carry the load current; the insulation , which has a colour or number code for identification and the outer sheath which may contain some means of providing protection from mechanical damage.

The conductors of a cable are made of either copper or aluminium and may be stranded or solid. Solid conductors are only used in fixed wiring installations and may be shaped in larger cables. Stranded conductors are more flexible and conductor sizes from 4.0 to 25 mm 2 contain seven strands. A 10 mm 2 conductor, for example, has seven 1.35 mm diameter strands which collectively make up the 10 mm 2 cross-sectional area of the cable. Conductors above 25 mm 2 have more than seven strands, depending upon

the size of the cable. Flexible cords have multiple strands of very fine wire, as fine as one strand of human hair. This gives the cable its very flexible quality.

These core colours must not be used after 31 March 2006.

Extensions or alterations to existing single-phase installations do not require marking at the interface between the old and new fixed wiring colours. However, a warning notice must be fixed at the consumer unit or distribution fuse board which states:

Caution – this installation has wiring colours to two versions of BS 7671. Great care should be taken before undertaking extensions, alterations or repair that all conductors are correctly identified.

Alterations to three-phase installations must be marked at the interface L1, L2, L3 for the lines and N for the neutral. Both new and old cables must be marked. These markings are preferred to coloured tape and a caution notice is again required at the distribution board.

Domestic and commercial installations use this cable, which may be clipped direct to a surface, sunk in plaster or installed in conduit or trunking. It is the simplest and least expensive cable. Figure 6.1 shows a sketch of a twin and earth cable. The conductors are covered with a colour-coded PVC insulation and then contained singly or with others in a PVC outer sheath.

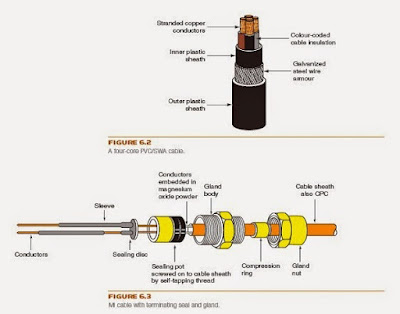

PVC insulated steel wire armour cables are used for wiring underground between buildings, for main supplies to dwellings, rising sub-mains and industrial installations. They are used where some mechanical protection of the cable conductors is required. The conductors are covered with colour-coded PVC insulation and then contained either singly or with others in a PVC sheath (see Fig. 6.2 ). Around this sheath is placed an armour protection of steel wires twisted along the length of the cable, and a fi nal PVC sheath covering the steel wires protects them from corrosion. The armour sheath also provides the circuit protective conductor (CPC) and the cable is simply terminated using a compression gland.

A mineral insulated (MI) cable has a seamless copper sheath which makes it waterproof and fi re- and corrosion-resistant. These characteristics often make it the only cable choice for hazardous or high-temperature installations such as oil refineries and chemical works, boiler houses and furnaces, petrol pump and fire alarm installations. The cable has a small overall diameter when compared to alternative cables and may be supplied as bare copper or with a PVC oversheath. It is colour-coded orange for general electrical wiring, white for emergency lighting or red for fi re alarm wiring. The copper outer sheath provides the CPC, and the cable is terminated with a pot and sealed with compound and a compression gland (see Fig. 6.3 ). The copper conductors are embedded in a white powder, magnesium oxide, which is non-ageing and non-combustible, but which is hygroscopic, which means that it readily absorbs moisture from the surrounding air, unless adequately terminated. The termination of an MI cable is acomplicated process requiring the electrician to demonstrate a high level of practical skill and expertise for the termination to be successful.

FP 200 cable is similar in appearance to an MI cable in that it is a circular tube, or the shape of a pencil, and is available with a red or white sheath. However, it is much simpler to use and terminate than an MI cable. The cable is available with either solid or stranded conductors that are insulated with ‘ insudite ’ a fire resistant insulation material. The conductors are then screened, by wrapping an aluminium tape around the insulated conductors, that is, between the insulated conductors and the outer sheath. This aluminium tape screen is applied metal side down and in contact with the bare CPC. The sheath is circular and made of a robust thermoplastic low smoke, zero halogen material. FP 200 is available in 2, 3, 4, 7, 12 and 19 cores with a conductor size range from 1.0 to 4.0 mm. The core colours are: two core, red and black, three core, red, yellow and blue and four core, black, red, yellow and blue. The cable is as easy to use as a PVC insulated and sheathed cable. No special terminations are required, the cable may be terminated through a grommet into a knock out box or terminated through a simple compression gland. The cable is a fire resistant cable, primarily intended for use in fire alarms and emergency lighting installations or it may be embedded in plaster.

The cables used for high-voltage power distribution require termination and installation expertise beyond the normal experience of a contracting electrician. The regulations covering high-voltage distribution are beyond the scope of the IEE regulations for electrical installations. Operating at voltages in excess of 33 KV and delivering thousands of kilowatts, these cables are either suspended out of reach on pylons or buried in the ground in carefully constructed trenches.

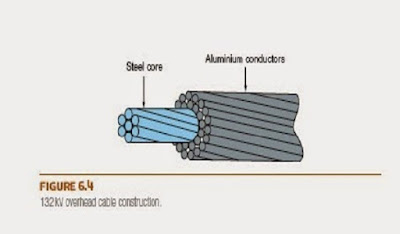

Suspended from cable towers or pylons, overhead cables must be light, flexible and strong.The cable is constructed of stranded aluminium conductors formed around a core of steel stranded conductors (see Fig. 6.4 ). The aluminium conductors carry the current and the steel core provides the tensile strength required to suspend the cable between pylons. The cable is not insulated since it is placed out of reach and insulation would only add to the weight of the cable.

Fixed cable core colours up to 2006

- Single-phase supplies red line conductors, black neutral conductors, and green combined with yellow for earth conductors.

- Three-Phase supplies red, yellow and blue line conductors, black neutral conductors and green combined with yellow for earth conductors.

These core colours must not be used after 31 March 2006.

New (harmonized) fixed cable core colours

- Single-phase supplies brown line conductors, blue neutral conductors and green combined with yellow for earth conductors (just like flexible cords).

- Three-phase supplies brown, black and grey line conductors, blue neutral conductors and green combined with yellow for earth conductors. Cable core colours from 31st of March 2004 onwards.

Extensions or alterations to existing single-phase installations do not require marking at the interface between the old and new fixed wiring colours. However, a warning notice must be fixed at the consumer unit or distribution fuse board which states:

Caution – this installation has wiring colours to two versions of BS 7671. Great care should be taken before undertaking extensions, alterations or repair that all conductors are correctly identified.

Alterations to three-phase installations must be marked at the interface L1, L2, L3 for the lines and N for the neutral. Both new and old cables must be marked. These markings are preferred to coloured tape and a caution notice is again required at the distribution board.

PVC insulated and sheathed cables

Domestic and commercial installations use this cable, which may be clipped direct to a surface, sunk in plaster or installed in conduit or trunking. It is the simplest and least expensive cable. Figure 6.1 shows a sketch of a twin and earth cable. The conductors are covered with a colour-coded PVC insulation and then contained singly or with others in a PVC outer sheath.

PVC/SWA cable

PVC insulated steel wire armour cables are used for wiring underground between buildings, for main supplies to dwellings, rising sub-mains and industrial installations. They are used where some mechanical protection of the cable conductors is required. The conductors are covered with colour-coded PVC insulation and then contained either singly or with others in a PVC sheath (see Fig. 6.2 ). Around this sheath is placed an armour protection of steel wires twisted along the length of the cable, and a fi nal PVC sheath covering the steel wires protects them from corrosion. The armour sheath also provides the circuit protective conductor (CPC) and the cable is simply terminated using a compression gland.

MI cable

A mineral insulated (MI) cable has a seamless copper sheath which makes it waterproof and fi re- and corrosion-resistant. These characteristics often make it the only cable choice for hazardous or high-temperature installations such as oil refineries and chemical works, boiler houses and furnaces, petrol pump and fire alarm installations. The cable has a small overall diameter when compared to alternative cables and may be supplied as bare copper or with a PVC oversheath. It is colour-coded orange for general electrical wiring, white for emergency lighting or red for fi re alarm wiring. The copper outer sheath provides the CPC, and the cable is terminated with a pot and sealed with compound and a compression gland (see Fig. 6.3 ). The copper conductors are embedded in a white powder, magnesium oxide, which is non-ageing and non-combustible, but which is hygroscopic, which means that it readily absorbs moisture from the surrounding air, unless adequately terminated. The termination of an MI cable is acomplicated process requiring the electrician to demonstrate a high level of practical skill and expertise for the termination to be successful.

FP 200 cable

FP 200 cable is similar in appearance to an MI cable in that it is a circular tube, or the shape of a pencil, and is available with a red or white sheath. However, it is much simpler to use and terminate than an MI cable. The cable is available with either solid or stranded conductors that are insulated with ‘ insudite ’ a fire resistant insulation material. The conductors are then screened, by wrapping an aluminium tape around the insulated conductors, that is, between the insulated conductors and the outer sheath. This aluminium tape screen is applied metal side down and in contact with the bare CPC. The sheath is circular and made of a robust thermoplastic low smoke, zero halogen material. FP 200 is available in 2, 3, 4, 7, 12 and 19 cores with a conductor size range from 1.0 to 4.0 mm. The core colours are: two core, red and black, three core, red, yellow and blue and four core, black, red, yellow and blue. The cable is as easy to use as a PVC insulated and sheathed cable. No special terminations are required, the cable may be terminated through a grommet into a knock out box or terminated through a simple compression gland. The cable is a fire resistant cable, primarily intended for use in fire alarms and emergency lighting installations or it may be embedded in plaster.

High-voltage power cables

The cables used for high-voltage power distribution require termination and installation expertise beyond the normal experience of a contracting electrician. The regulations covering high-voltage distribution are beyond the scope of the IEE regulations for electrical installations. Operating at voltages in excess of 33 KV and delivering thousands of kilowatts, these cables are either suspended out of reach on pylons or buried in the ground in carefully constructed trenches.

High-voltage overhead cables

Suspended from cable towers or pylons, overhead cables must be light, flexible and strong.The cable is constructed of stranded aluminium conductors formed around a core of steel stranded conductors (see Fig. 6.4 ). The aluminium conductors carry the current and the steel core provides the tensile strength required to suspend the cable between pylons. The cable is not insulated since it is placed out of reach and insulation would only add to the weight of the cable.

Source: Basic Electrical Installation Work

FIFTH EDITION

TREVOR LINSLEY

Senior Lecturer

Blackpool and The Fylde College

Znergy Cable offers top-quality fire proof cables engineered to withstand the most demanding electrical environments. Our Electrical Cable Australia range is designed with advanced materials and rigorous testing to ensure maximum safety and performance. Whether for industrial, commercial, or residential applications, our fire proof cables provide peace of mind, delivering reliable power transmission without compromise. Trust Znergy Cable for unparalleled durability and safety in your electrical installations across Australia.

ReplyDeletePost a Comment